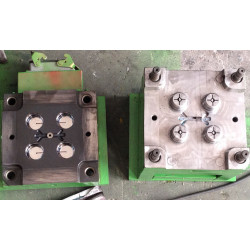

ABS Thermostat Damper Knob injection tool, 35 days finishing, guaranty shot 500,000 cycle

ABS Thermostat Damper Knob injection tool specs:

Product size:O.D.37.8x29mm

Material: ABS

Cavities: 4

Injection gate:Pin gate

Cavity & Core material: German 2738

Mould size:300x240x280mm

Why buy plastic injection moulds from china?

Mostcustomers come to China to find cost-effective but good quality mouldsuppliers, since mould made in China costs only 20~70% of European, American orJapanese, also more costly than Korea and Taiwan.

Cometo order China mould earlier, it will evident that you are wiser. If yourcompetitors are ordering China Mould to save mould & product cost while youare investing 30~80% more than them.

Why buy plastic injection moulds from us?

Amongthousands of mould suppliers in China, always you can find endless cheaperprice. But we are aiming to supply best quality which in compliance with the price customer paid, but not cheapest price with relevant low quality.

Ourmould factory has over 30 years experiences, can do qualified mould making basedon high mould making philosophy & fair cost controlling.

Our mould design philosophy as:

-To be a long life & high performance mould Design

-To be machinable and precision machining achievable mold components andmechanical design

-To be the most economical mould design for the customer

General plastic injection mould specifications:

General capabilities | Design-Engineering-Fabricate-Modification |

Die field | Home appliance & sundry plastic ware. |

Mould material | P20,H718,2738 etc., steel grade and brand as per customer request |

Production equipment | CNC machine 3pcs, CNC engraving machine 3pcs,electric sparkle 5pcs, linear cutter 7pcs, drilling machine 16pcs, grinding machine 1pc, milling machine 2pcs, |

Production capacity | 300sets per year |

File formats | Pro-E, UGSNX3, Cimatron, Auto CAD & Solid works, MoldFlow |

Additionalservices including:

Inject custom parts and components

Our factory owns professional injection molding workshop with numerical controlinjection machine with capabilities from 60 to 1500Tons.

We excel in producing a limitless variety and sizes of custom injection partsand components used in industrial and commercial assemblies, all made to yourexact specifications.

Also especially we owns one full automatic electro-chrome-plating line whichoffers high quality chrome plated plastic part to our customers.

Surface finishes including:

- Chrome plating

- Spray painting

- Printing

- Customer parts assembly including: with metal part, aluminum part, copper part

- Tel

- *Title

- *Content

- Name:

- Mr.Zeng

- Tel:

+86-571-86433485

+86-137-32202800

+86-189-58129996

- Email:

- sales@fridgtec.com

- WhatsApp:

- 8613732202800

- Skype:

- Skype:hzpkrichz

- Address:

- Rm 910, Baideli Bldg, No.519, Gonglian Rd,Binjiang, Hangzhou,China